High Quality Drawer Slides

and Cabinet Hinges Supplier in China

Quality is at the heart of every drawer slide and cabinet hinge production at Baoertai. We are committed to providing our customers with the highest standard of drawer slides and cabinet hinges.

Strict Control of Drawer Slide and Cabinet Hinge Production Lines

We have subdivided quality control into several stages to realize all-round control from raw materials to finished products.

Raw Material Inspection

Raw materials are the foundation of product quality. Different requirements, and our firm will carry out strict screening and checking standards in the manufacturing process to meet the key raw material conditions, such as stainless steel and cold rolled steel.

Our company maintains close relationships with suppliers. Because of this, raw material traceability can be done effectively, which is very important for guaranteeing the product quality and performance requirements.

Our company maintains close relationships with suppliers. Because of this, raw material traceability can be done effectively, which is very important for guaranteeing the product quality and performance requirements.

● Thickness 1.0mm - 1.2mm

● Composition stainless steel, cold rolled steel

● Tolerance ±0.1mm or less

● No surface scratches, dents, corrosion

● Material from top steel mills

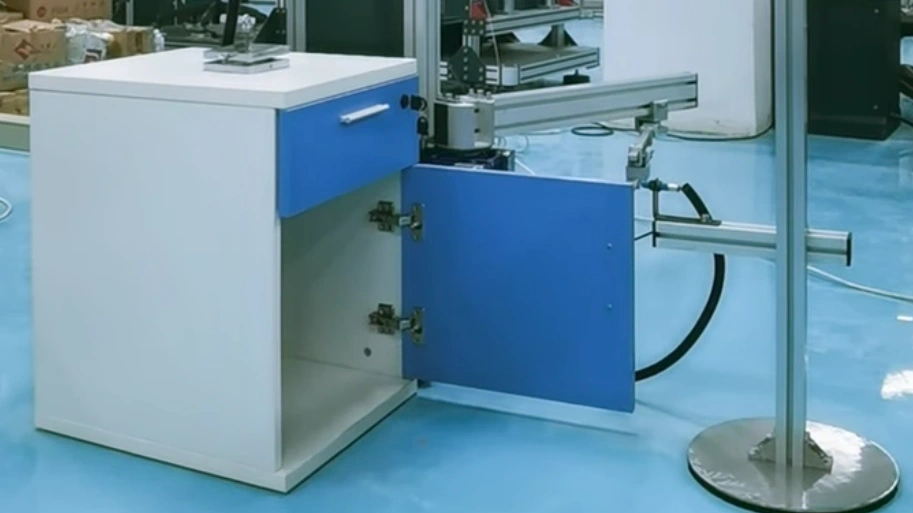

Production Process Quality Control

In the production process, all the advanced automated production lines are monitored in real-time.

From data collection, data analysis, it finds out the deviation in the production as soon as possible and corrects it quickly. It not only improves the efficiency of production but also drastically reduces human errors.

From data collection, data analysis, it finds out the deviation in the production as soon as possible and corrects it quickly. It not only improves the efficiency of production but also drastically reduces human errors.

100% Comprehensive Inspection Before Delivery

After the goods are ready, we will make a 100% quality check for every batch of drawer slides and cabinet hinges

We will check strictly in appearance, size, function, and performance to make sure every product meets the standard of design before leaving our factory.

We will check strictly in appearance, size, function, and performance to make sure every product meets the standard of design before leaving our factory.

Attention to Every Detail of High Quality Drawer Slides and Cabinet Hinges Produces Durable, Stable and Reliable Products.

All Quality ProductsRigorous Testing Process

We understand that quality is key for hardware accessories like drawer slides and cabinet hinges. We implement testing programs to ensure that our products meet the industry's highest standards.

Load Bearing Test

Ensure the slides and hinges will function smoothly within the weight range of daily use and remain safe and reliable under extreme load conditions without risk of damage or loss of function.

Procedure:

1.Mount the drawer slides or hinges onto a test device so as to simulate an actual use environment.

2. It's usually progressive, starting with the design load, which increases progressively up to a load exceeding the limit of the normal use conditions.

3. Performance of the product against the variable weights should be monitored. Distortion, poor sliding, looseness or other forms of damage should be observed.

Procedure:

1.Mount the drawer slides or hinges onto a test device so as to simulate an actual use environment.

2. It's usually progressive, starting with the design load, which increases progressively up to a load exceeding the limit of the normal use conditions.

3. Performance of the product against the variable weights should be monitored. Distortion, poor sliding, looseness or other forms of damage should be observed.

Pulling Test

Perform repetitive, long-duration pulling and pulling to simulate usage so that smooth operation and durability can be maintained with the drawer slides or hinges under frequent opening and closing.

Procedure:

1.Drawer slides or hinges are taken through a cycle of continuous opening and closing or pulling motions using automated test equipment.

2.Most industry standards call for tens of thousands of cycle tests to simulate years of daily use.

3.At each critical phase, slides or hinges are inspected for smoothness, positioning accuracy as well as imperfections such as seizing, free play or rattling.

Procedure:

1.Drawer slides or hinges are taken through a cycle of continuous opening and closing or pulling motions using automated test equipment.

2.Most industry standards call for tens of thousands of cycle tests to simulate years of daily use.

3.At each critical phase, slides or hinges are inspected for smoothness, positioning accuracy as well as imperfections such as seizing, free play or rattling.

Salt Spray Test

Objective: It determines the rust resistance in drawer slides or cabinet hinges when exposed to a corrosive atmosphere with humidity for a long period of time, under conditions that ensure no rust or corrosion occurred. This is especially suitable for kitchens, bathrooms, and other high-humidity usage environments.

Procedure:

1.Drawer slides or hinges are placed inside a salt spray box to simulate exposure to a corrosive atmosphere in a very long period.

2.A water spray with a high salt concentration continuously stems from the salt spray chamber. The usual test duration ranges from 24 to 96 hours depending on the product application and customer requirement.

3.At the end of the test, the product surface is checked for any rust, corrosion or flaking of the surface coat.

Procedure:

1.Drawer slides or hinges are placed inside a salt spray box to simulate exposure to a corrosive atmosphere in a very long period.

2.A water spray with a high salt concentration continuously stems from the salt spray chamber. The usual test duration ranges from 24 to 96 hours depending on the product application and customer requirement.

3.At the end of the test, the product surface is checked for any rust, corrosion or flaking of the surface coat.

Hinge closure testing

The hinges shall ensure soft movement of the damping closure function in order not to create violent impact in case of a door or drawer closure; it offers silent and safe closure to users.

Operating Procedure:

1. Open the hinge repeatedly and shut it to simulate the closing action of the hinge in normal use.

2.Test if the buffer mechanism works well every time in the closing process, so that the closing motion be smooth and there is no collision sound.

2. High frequency opening and closing test, often tens of thousands of times for simulating its performance after long time use.

4.Cushioning force, velocity at the end of the closing and whether the hinge can prevent sudden impacts are measured.

Operating Procedure:

1. Open the hinge repeatedly and shut it to simulate the closing action of the hinge in normal use.

2.Test if the buffer mechanism works well every time in the closing process, so that the closing motion be smooth and there is no collision sound.

2. High frequency opening and closing test, often tens of thousands of times for simulating its performance after long time use.

4.Cushioning force, velocity at the end of the closing and whether the hinge can prevent sudden impacts are measured.

Certifications and Industry Standards

Our quality control processes follow internationally recognized standards and are ISO 9001 certified, ensuring that our products constantly meet and often exceed industry requirements. We are proud to be a trusted partner for many companies in different parts of the world by providing hardware solutions that have undergone rigorous testing and prove their worth.